john deere skid steer bucket pin removal Skid steer pin is plugged up and wont take grease anymore. It's a simple repair . R17Z-9A is a zero-tail swing excavator with a Tier 4 Final KUBOTA engine and a standard bucket. It has a net power of 15.8 hp, an operating weight of 1,780 kg, and a maximum digging depth of 2,200 mm.

0 · youtube skid steer pin repair

1 · tapered pin removal john deere

2 · skidsteer tapered pin removal

3 · skid steer pin replacement

4 · skid steer pin removal

5 · john deere skid steer removal

6 · john deere skid steer cylinder replacement

7 · 2000 john deere skid steer removal

I need to buy a mini excavator for my business. Which type of trailer is considered best for these? Flatbed with ramps? Car hauler? Dump? Also, I'm assuming 20ft. Or is shorter better?

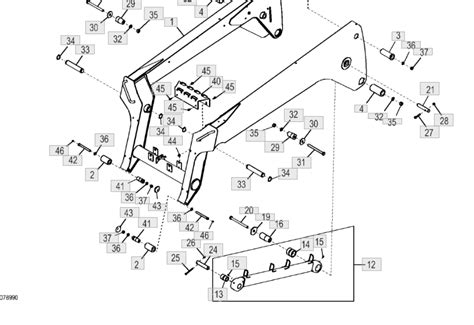

I'm trying to remove the tapered pin from the loader arm (number 41 in this image). I was able to remove the bolt and nut (42 and 37) and tried to heat the arm and drive the pin from the outside in.

Remove the bobtach and bucket from the machine. Remove the grease zerks from each sid.

youtube skid steer pin repair

tapered pin removal john deere

Skid steer pin is plugged up and wont take grease anymore. It's a simple repair . Remove the bobtach and bucket from the machine. Remove the grease zerks . How to remove the wedge style pins that hold John Deere and New Holland skid steer cylinders in place. This particular model is a 2000 John Deere 240z.

This tutorial shows how to attach and detach buckets and other attachments . After spending another hour of pounding and heat to straighten the quick attach . If it's a brass type bushing, another method for removal that I have used is a . With a large enough set you could probably push the pin in and get the bucket .

I'm trying to remove the tapered pin from the loader arm (number 41 in this image). I was able to remove the bolt and nut (42 and 37) and tried to heat the arm and drive the pin from the outside in.Skid steer pin is plugged up and wont take grease anymore. It's a simple repair it just takes a little time. From start to finish. Thanks for watching and ha. Remove the bobtach and bucket from the machine. Remove the grease zerks from each side. You can elevate the back of the assembly where penetrating fluid will pond around the pins.

How to remove the wedge style pins that hold John Deere and New Holland skid steer cylinders in place. This particular model is a 2000 John Deere 240z.Boom pin? See the link below. The pins are tapered, use a large socket or hollow spacer on the bolt side, and use the bolt with a washer on the inner side and pull the pin by tightening the bolt. This tutorial shows how to attach and detach buckets and other attachments from skid steers and compact track loaders. Our example shows how to attach and de.

After spending another hour of pounding and heat to straighten the quick attach and bucket back into shape, I can now remove the pins without a hammer. I think the next option was a handful of C4. If it's a brass type bushing, another method for removal that I have used is a sharp, oval shape, carbide burr in a die grinder. Simply move the burr across the bottom of the bushing and grind a groove in it. A good sharp burr will cut a trench in it fairly quickly.This should loosen the pin, then take the bolt out and simply tap out the pin. ( The pin is CONE shaped ). I would take the bucket off to lessen the weight, might even suspend the bucket mount with an engine hoist, it is somewhat heavy also.Remove the pin retainer and then you should be able to drive the pin out as long as it is not seized in the bushing and that you have removed all weight or pressure on the attachment to allow the pin to be removed.

skidsteer tapered pin removal

I'm trying to remove the tapered pin from the loader arm (number 41 in this image). I was able to remove the bolt and nut (42 and 37) and tried to heat the arm and drive the pin from the outside in.Skid steer pin is plugged up and wont take grease anymore. It's a simple repair it just takes a little time. From start to finish. Thanks for watching and ha. Remove the bobtach and bucket from the machine. Remove the grease zerks from each side. You can elevate the back of the assembly where penetrating fluid will pond around the pins.How to remove the wedge style pins that hold John Deere and New Holland skid steer cylinders in place. This particular model is a 2000 John Deere 240z.

Boom pin? See the link below. The pins are tapered, use a large socket or hollow spacer on the bolt side, and use the bolt with a washer on the inner side and pull the pin by tightening the bolt. This tutorial shows how to attach and detach buckets and other attachments from skid steers and compact track loaders. Our example shows how to attach and de.

After spending another hour of pounding and heat to straighten the quick attach and bucket back into shape, I can now remove the pins without a hammer. I think the next option was a handful of C4.

If it's a brass type bushing, another method for removal that I have used is a sharp, oval shape, carbide burr in a die grinder. Simply move the burr across the bottom of the bushing and grind a groove in it. A good sharp burr will cut a trench in it fairly quickly.This should loosen the pin, then take the bolt out and simply tap out the pin. ( The pin is CONE shaped ). I would take the bucket off to lessen the weight, might even suspend the bucket mount with an engine hoist, it is somewhat heavy also.

skid steer pin replacement

skid steer pin removal

john deere skid steer removal

john deere skid steer cylinder replacement

Looking to buy a used Ihi excavators? Browse our extensive inventory of new and used Ihi excavators from local Ihi dealers and private sellers. Compare prices, models, trims, options and specifications between different Ihi excavators on Equipment Trader.

john deere skid steer bucket pin removal|skidsteer tapered pin removal