skid steer vertical vs radial lift Learn the differences and similarities of radial lift and vertical lift skid steer loaders, and how to choose the right one for your job. Radial lifts are better for digging and grading, while vertical lifts are better for stacking and drilling. Buckets: Standard digging buckets generally weigh between 100 and 500 pounds, depending on their size and capacity. Augers: Augers typically weigh between 150 and 400 pounds, depending on the length and diameter of the auger bit.

0 · vertical vs radial loader

1 · vertical vs radial lift steer

2 · vertical vs radial lift

3 · vertical skid steer vs radial

4 · vertical lift skid steer

5 · radial lift skid steer

6 · forklift vs skid steer

7 · bobcat vertical lift vs radial

IC Mini Digger Hire | Digger and Man Hire | Footings | Foundations | Driveways | Drainage | Levelling | Based in Kent - Maidstone, Chatham, Medway & Surrounding Areas

Learn the differences and similarities of radial lift and vertical lift skid steer loaders, and how to choose the right one for your job. Radial lifts are better for digging and grading, while vertical lifts are better for stacking and drilling.A vertical lift loader makes loading dump trucks easier. The machine’s maximum height allows .

Radial-arm skid steers are good for excavating, grading and digging below .

Understanding the differences between radial and vertical lift skid steers is . Radial-arm skid steers are best for excavating, grading and digging below .

Learn the differences and similarities of radial lift and vertical lift skid steer loaders, and how to choose the right one for your job. Radial lifts are better for digging and grading, while vertical lifts are better for stacking and drilling.A vertical lift loader makes loading dump trucks easier. The machine’s maximum height allows a bucket to reach completely inside a truck to dump the load. Because the bucket on a vertical design rises and turns at the same time, your overall dimensions remain constant.

vertical vs radial loader

Radial-arm skid steers are good for excavating, grading and digging below grade. Vertical-lift machines are ideal for material handling.

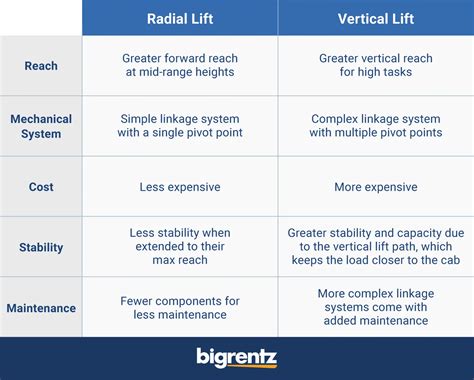

Learn the difference between radial and vertical lift skid steers and compact track loaders, and how to choose the best one for your project. Compare the pros and cons, lift capacity, reach, stability, and visibility of each type of machine. Understanding the differences between radial and vertical lift skid steers is crucial for selecting the right equipment for your project. Radial lift skid steers offer superior forward reach and affordability, making them ideal for ground-level work and budget-conscious projects.

Radial-arm skid steers are best for excavating, grading and digging below grade. Vertical-lift machines are ideal for unloading material off trucks and loading dirt into a dump truck. "It depends if they are loading and unloading flatbed trucks. For that, radial-lift is better.

The most common question asked by skid steer customers is, “Which style of skid steer is better, radial lift or vertical lift?” The answer is both. The choice between radial lift and vertical lift design on a skid steer or track loader depends entirely on the application.

vertical vs radial lift steer

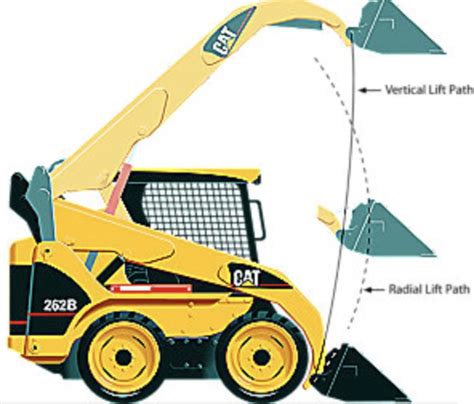

The difference between vertical lift and radial lift involves the path that the load takes as it is being lifted. This path is a direct result of the geometry of the skid steer (or compact track loader) arm. On a radial lift machine, the load follows a curved path.

Learn the differences and advantages of radial and vertical skid steer loader designs for various applications. Radial loaders are simpler, stronger, and more stable, while vertical loaders are more versatile, balanced, and have higher capacity. At their core, both radial-lift and vertical-lift skid steers excel in tasks like loading, debris clearing, and site leveling. The primary difference lies not in their capabilities, but in how they apply them, particularly in their lift path geometries.

Learn the differences and similarities of radial lift and vertical lift skid steer loaders, and how to choose the right one for your job. Radial lifts are better for digging and grading, while vertical lifts are better for stacking and drilling.A vertical lift loader makes loading dump trucks easier. The machine’s maximum height allows a bucket to reach completely inside a truck to dump the load. Because the bucket on a vertical design rises and turns at the same time, your overall dimensions remain constant.

Radial-arm skid steers are good for excavating, grading and digging below grade. Vertical-lift machines are ideal for material handling. Learn the difference between radial and vertical lift skid steers and compact track loaders, and how to choose the best one for your project. Compare the pros and cons, lift capacity, reach, stability, and visibility of each type of machine.

Understanding the differences between radial and vertical lift skid steers is crucial for selecting the right equipment for your project. Radial lift skid steers offer superior forward reach and affordability, making them ideal for ground-level work and budget-conscious projects. Radial-arm skid steers are best for excavating, grading and digging below grade. Vertical-lift machines are ideal for unloading material off trucks and loading dirt into a dump truck. "It depends if they are loading and unloading flatbed trucks. For that, radial-lift is better. The most common question asked by skid steer customers is, “Which style of skid steer is better, radial lift or vertical lift?” The answer is both. The choice between radial lift and vertical lift design on a skid steer or track loader depends entirely on the application. The difference between vertical lift and radial lift involves the path that the load takes as it is being lifted. This path is a direct result of the geometry of the skid steer (or compact track loader) arm. On a radial lift machine, the load follows a curved path.

vertical vs radial lift

Learn the differences and advantages of radial and vertical skid steer loader designs for various applications. Radial loaders are simpler, stronger, and more stable, while vertical loaders are more versatile, balanced, and have higher capacity.

ditch witch sk350

42 mini skid steer root grapple

United Rentals offers a variety of mini excavators for rent, ideal for confined applications such as trenching, backfilling or digging. Find out the operating weight, dig depth, tail swing and power of different models and learn how to operate a mini excavator.

skid steer vertical vs radial lift|vertical vs radial loader