adding auxiliary hydraulics to skid steer I also have a 1999 L565 I want to add auxiliary hydraulics to it. Did you buy a kit . Mammoth Hire is your local tool and equipment hire shop for Barnstaple. With over 10,000 products to choose from including carpet cleaners, cement mixers, mini diggers, floor sanders, .

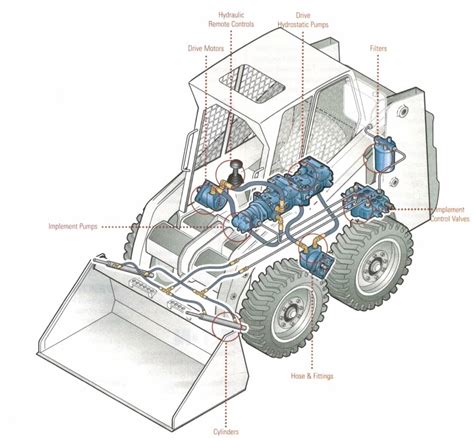

0 · skid steer hydraulic schematic

1 · skid steer auxiliary hydraulic couplers

2 · skid steer auxiliary hydraulic coolers

3 · hydraulic attachments for skid steer

4 · extra auxiliary hydraulics for excavators

5 · bobcat 873 auxiliary hydraulic problems

6 · auxiliary hydraulic kits for backhoes

7 · adding auxiliary hydraulics to tractor

Looking for a cost-effective small digger to help with construction or groundworks in Worthing, Lancing, Durrington or the West Sussex area? We have mini and micro diggers available for .

This is by no means a complete list however it is most of what I purchased from Surplus Center. Unfortunately the part numbers didn't transfer. Obviously you. I also have a 1999 L565 I want to add auxiliary hydraulics to it. Did you buy a kit . how to hook up auxiliary hydraulics bobcat hydraulic connection tips We show the proper way to connect your Bobcat skid steer auxiliary hydraulic hoses for i. Learn the basics and nuances of auxiliary hydraulics systems on skid steers .

The accessory output on a skid steer is not another pump. You remove the proper plugs on the spool valve and attach a piggyback unit on to the power control valve. What you are looking at in a kit is the piggyback spool valve, the control linkage for the valve, and the plumbing for the power attachment.

These 500 and 600 series units are marketed to construction folks with heavy skid steers producing heavier hydraulic flows and pressures. Nevertheless, I have the shop manual for the tractor I plan to examine for possible cavitation of the auxiliary hydraulic pump on the tractor, so thank you for that idea. Re skid steer, it may depend on the make of machine. My Bobcat 743B uses engine oil 20-50W in the hydraulics as per the owners manual.

Machine in question is a mid 2000's Deere 332 skid loader. Wheel motor failed and owner is selling it as is. Sounds like one of the bearings failed. Shavings were found in the hydraulic filter. I would like to buy it to fix for my own use. The process of replacing the motor and hooking everything back up isn't a big deal. I worked on a large 1960's Clark forklift that had slow hydraulics. I found that it had a large fine screen in the tank at the pump pick up. The screen was sucked into a tight knot from being stopped up. I cleaned and straightened the screen and it acted like a new forklift! You might need to change that oil more than once if it has a lot of water.

skid steer hydraulic schematic

I’m looking for a few pointers on adding live hydraulics to a press. The press is a 75 ton Dake. I have a remote hydraulic unit but I’m not sure how to tie it into the hydraulics on the press, somehow it needs a by pass, right? My skid steer ( different brand a ASV a 2006) has three safety switches The door, one under the seat and the lap bar hooked in a series. Some skid steers the seat belt has to be used. It sound like a lot of safety features until you hear of . JCB = Volvo in the skid steer department. They are the same machine. Have you ever adjusted the drive chain tension? If the chains are loose, it can really hammer the motors and other drive components. On a Bobcat, if you jack up the rear wheels, you are supposed to have 1/4" of rotation at the outside of the tire.

For material handling inside the shop, I'd suggest a forklift - not a skid steer. I have both. I have several pallet racks in my shop, so a "reacher - picker" style of electric forklift is what I use. The only time that the skid steer has come into the shop is to move large equipment around.

Icehd81 - I will need to plumb in a gauge, there aren't any in the system right now. The best I can describe the noise I hear is an intermittent screeching/pulsing. The hydraulics are very slow, jerky and have no strength. The tractor was working working OK in early September, I next used it at the end of the month and the hydraulics didn't work.

The accessory output on a skid steer is not another pump. You remove the proper plugs on the spool valve and attach a piggyback unit on to the power control valve. What you are looking at in a kit is the piggyback spool valve, the control linkage for the valve, and the plumbing for the power attachment. These 500 and 600 series units are marketed to construction folks with heavy skid steers producing heavier hydraulic flows and pressures. Nevertheless, I have the shop manual for the tractor I plan to examine for possible cavitation of the auxiliary hydraulic pump on the tractor, so thank you for that idea. Re skid steer, it may depend on the make of machine. My Bobcat 743B uses engine oil 20-50W in the hydraulics as per the owners manual. Machine in question is a mid 2000's Deere 332 skid loader. Wheel motor failed and owner is selling it as is. Sounds like one of the bearings failed. Shavings were found in the hydraulic filter. I would like to buy it to fix for my own use. The process of replacing the motor and hooking everything back up isn't a big deal.

I worked on a large 1960's Clark forklift that had slow hydraulics. I found that it had a large fine screen in the tank at the pump pick up. The screen was sucked into a tight knot from being stopped up. I cleaned and straightened the screen and it acted like a new forklift! You might need to change that oil more than once if it has a lot of water. I’m looking for a few pointers on adding live hydraulics to a press. The press is a 75 ton Dake. I have a remote hydraulic unit but I’m not sure how to tie it into the hydraulics on the press, somehow it needs a by pass, right? My skid steer ( different brand a ASV a 2006) has three safety switches The door, one under the seat and the lap bar hooked in a series. Some skid steers the seat belt has to be used. It sound like a lot of safety features until you hear of . JCB = Volvo in the skid steer department. They are the same machine. Have you ever adjusted the drive chain tension? If the chains are loose, it can really hammer the motors and other drive components. On a Bobcat, if you jack up the rear wheels, you are supposed to have 1/4" of rotation at the outside of the tire.

For material handling inside the shop, I'd suggest a forklift - not a skid steer. I have both. I have several pallet racks in my shop, so a "reacher - picker" style of electric forklift is what I use. The only time that the skid steer has come into the shop is to move large equipment around.

cab door for cat 287b skid steer

bruder roadmax skid steer

We offer a "Click & Collect" service from locations nationwide, and we can deliver to your home .

adding auxiliary hydraulics to skid steer|hydraulic attachments for skid steer